すべての製品

-

リチャード「XIWUERは非常に革新的である。それらは先読みする優秀で、直観的なサービスを私達が」。かもしれないものをに関して未来に必要とする提供した

リチャード「XIWUERは非常に革新的である。それらは先読みする優秀で、直観的なサービスを私達が」。かもしれないものをに関して未来に必要とする提供した -

マイク「私達の厳しい処理の条件を満たすように異なった指定の設計へのXIWUER献呈研究開発の私達の年へ遺言」はである。

マイク「私達の厳しい処理の条件を満たすように異なった指定の設計へのXIWUER献呈研究開発の私達の年へ遺言」はである。 -

結婚しなさい「XIWUER印象的な研究の機能があり、よいプロトタイピングの機能および高い製品品質」を示す。

結婚しなさい「XIWUER印象的な研究の機能があり、よいプロトタイピングの機能および高い製品品質」を示す。

コンタクトパーソン :

Wang Hong

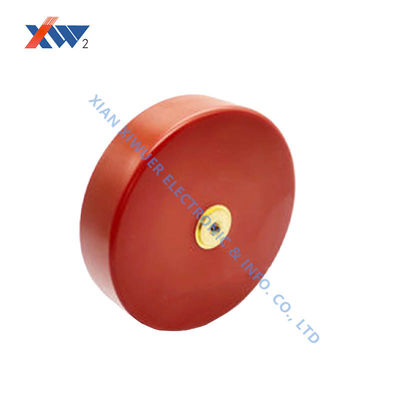

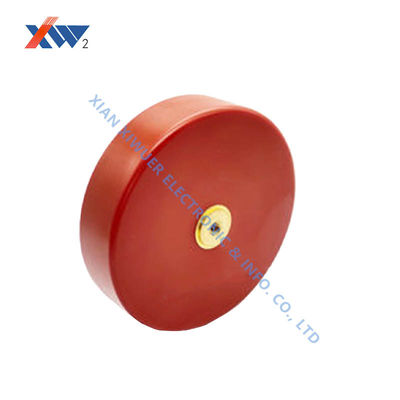

EB-PVD機器のための低分散性,高耐圧性,高隔熱性を持つカスタマイズされた超高電圧ドアノブコンデンサータ

試供品およびクーポンのための私に連絡しなさい。

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x商品の詳細

| ハイライト | 低分散 高電圧 ドアノブ コンデンサ,高耐電圧超高電圧コンデンサ,高い保温抵抗性EB-PVDコンデンサ |

||

|---|---|---|---|

製品の説明

高電圧 ドアハンドル コンデンサ

電子ビーム物理蒸気堆積装置 (EB-PVD) の超高電圧コンデンサータソリューション

製品仕様

| 違う 違う | 仕様 | 消化 | 電圧 に 耐える | 断熱抵抗 | 尺寸 (mm) |

|---|---|---|---|---|---|

| 1 | 20kV-2000pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:45 H:19 L:23 D:12 M: ありがとう ありがとう5 |

| 2 | 20kV~10000pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:65 H:15 L:19 D:12 M: M: M: M:5 |

| 3 | 20kV~18000pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:80 H: 17 L: 25 D: 12 M:5 |

| 4 | 30kVから1000pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:45 H:24 L:32 D:12 M: ほら ほら4 |

| 5 | 30kV-2700pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:60 H:20 L:28 D:12 M:604 |

| 6 | 30kVから12000pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:45 H:19 L:23 D:12 M: ありがとう ありがとう5 |

| 7 | 40kV~150pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:74 H:18 L:26 D:12 M:M:5 |

| 8 | 40kVから500pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:28 H:33 L:41 D:8 M: ありがとう4 |

| 9 | 40kV~7500pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:80 H:24 L:29 D:12 M:80 D:806 |

| 10 | 40kV~10000pF | ≤0.0040 | 1.5Ur● 1分 | ≥1.0 x 105MΩ | D:80 H:22 L:26 D:16 M:805 |

非標準的な電力ソリューション

電子ビーム物理蒸気堆積装置 (EB-PVD) のための超高電圧コンデンサータソリューション

EB-PVD 技術の要件

EB-PVD技術は,高性能熱障壁コーティング (航空機エンジンのブレードなど) を堆積するために使用されます.原子炉の基本原理は 原子炉の原材料を 高エネルギーの電子束で 爆撃して蒸発させることですこの技術には

- 非常高電圧 (通常は10〜100kV)

- 極度に精密な電子束の電流制御

なぜ EB-PVD は パーソナライズ された コンデンサ 器 が 必要 な の です か

- 極度の電圧:電子銃の加速電圧は,200kVを超える単一のコンデンサーまたは連続で複数のコンデンサーを必要とする場合があります.

- 電圧バランスと信頼性連続アプリケーションでは,単点断裂を防ぐため,電圧分布が均等である必要があります.

- 空間制限と統合コンパクトな機器構造には,非標準の寸法や統合された部品が必要である.

調整 できる 能力

私たちは最先端の材料加工アプリケーションに 合わせたソリューションを提供しています

超高電圧のカスタマイズ

- 単体コンデンサター 300kV以上の電圧

- シリアル用用容量値を正確にマッチしたコンデンサータバンク

- 選択可能な統合型グレード抵抗器

構造的カスタマイズ

- カスタムコンデンサータ形,マウント方法,端末の向き

- 超高真空アプリケーション用,放出速度制御用の特殊バージョン

- クリーンルーム処理の選択肢

システムレベルのカスタマイズ

- 前編成された高電圧コンデンサター抵抗モジュール

- 完全な内部接続と隔熱

- "プラグアンドプレイ"の統合により 導入時間が短くなり リスクも軽減

私たちは,本当に最先端のプロセス機器は,そのコアコンポーネントの深いカスタマイズを必要とします.独自の超高電圧エネルギーソリューションを EB-PVDシステムに.

推薦されたプロダクト