-

リチャード「XIWUERは非常に革新的である。それらは先読みする優秀で、直観的なサービスを私達が」。かもしれないものをに関して未来に必要とする提供した

リチャード「XIWUERは非常に革新的である。それらは先読みする優秀で、直観的なサービスを私達が」。かもしれないものをに関して未来に必要とする提供した -

マイク「私達の厳しい処理の条件を満たすように異なった指定の設計へのXIWUER献呈研究開発の私達の年へ遺言」はである。

マイク「私達の厳しい処理の条件を満たすように異なった指定の設計へのXIWUER献呈研究開発の私達の年へ遺言」はである。 -

結婚しなさい「XIWUER印象的な研究の機能があり、よいプロトタイピングの機能および高い製品品質」を示す。

結婚しなさい「XIWUER印象的な研究の機能があり、よいプロトタイピングの機能および高い製品品質」を示す。

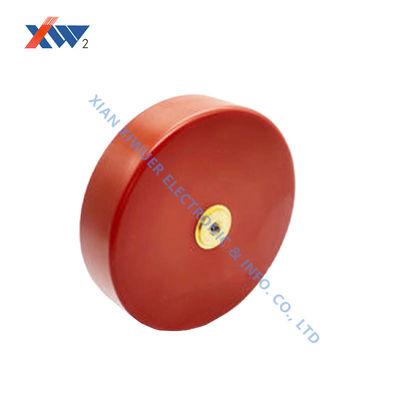

Long-term reliability of high-voltage doorknob capacitors in continuously operating spectrometers

試供品およびクーポンのための私に連絡しなさい。

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 消化 | ¥0.0040 | 抵抗電圧 | 1.5ur●1分 |

|---|---|---|---|

| 絶縁抵抗 | ≧1.0×105mΩ | ||

| ハイライト | high voltage doorknob capacitors for spectrometers,long-lasting doorknob capacitors high voltage,reliable spectrometer capacitors with high voltage |

||

Long-term reliability of high-voltage doorknob capacitors in continuously operating spectrometers

Drawing:![]()

Parameters:

| No. | Specification | Dissipation | Withstanding voltage | Insulation resistance | Dimension(mm) | ||||

| 1 | 20kV-2000pF |

≦0.0040 |

1.5Ur● 1min |

≧1.0×105MΩ |

D | H | L | D | M |

| 2 | 20kV-10000pF | 45 | 19 | 23 | 12 | 5 | |||

| 3 | 20kV-18000pF | 65 | 15 | 19 | 12 | 5 | |||

| 4 | 30kV-1000pF | 80 | 17 | 25 | 12 | 5 | |||

| 5 | 30kV-2700pF | 45 | 24 | 32 | 12 | 4 | |||

| 6 | 30kV-12000pF | 60 | 20 | 28 | 12 | 4 | |||

| 7 | 40kV-150pF | 20 | 33 | 41 | 8 | 4 | |||

| 8 | 40kV-500pF | 28 | 33 | 41 | 8 | 4 | |||

| 9 | 40kV-7500pF | 80 | 24 | 29 | 12 | 6 | |||

| 10 | 40kV-10000pF | 80 | 22 | 26 | 16 | 5 | |||

| 11 | 50kV-1000pF | 50 | 30 | 34 | 12 | 4 | |||

| 12 | 50kV-1000pF | 32 | 27 | 31 | 16 | 5 | |||

| 13 | 50kV-5600pF | 80 | 31 | 35 | 16 | 5 | |||

| 14 | 60kV-1500pF | 50 | 31 | 34 | 12 | 5 | |||

| 15 | 60kV-3000pF | 65 | 32 | 35 | 16 | 5 | |||

| 16 | 100kV-500pF | 50 | 54 | 58 | 12 | 5 | |||

| 17 | 100kV-2000pF | 51 | 32 | 35 | 16 | 5 | |||

| 18 | Insulator type 100kV-1500pF | 68 | 36 | 40 | 16 | 5 | |||

| 19 | 150kV-820pF | 65 | 95 | 100 | 12 | 5 | |||

| 20 | 200kV-600pF | 50 | 90 | 94 | 16 | 5 | |||

As core equipment supporting cutting-edge research in chemistry, biology, and materials science, the value of nuclear magnetic resonance (NMR) instruments lies in their long-term, stable, and highly reproducible data output. An unplanned downtime or insidious performance degradation can disrupt important kinetic experiments or render data from multiple samples incomparable. High-voltage doorknob capacitors, core components of high-voltage power supplies and radio frequency systems, are directly impacted by their long-term reliability and lifespan consistency, ensuring the continuity of scientific research and data quality.

The Harsh Operating Conditions of Capacitors in Nuclear Magnetic Resonance (NMR) Instruments

Continuous High-Voltage Stress: In the DC link of the magnet power supply and RF power amplifier, capacitors operate at their rated high voltage for extended periods, placing a constant strain on the dielectric strength of the dielectric.

Frequent Pulse Shocks: In RF pulse power supplies, capacitors must undergo frequent charge and discharge cycles at experimental repetition rates (up to hundreds of Hz), withstanding the shocks of current and thermal stress.

Striving for Extreme Maintenance Intervals: NMR instruments typically have short annual maintenance schedules, requiring critical internal components to maintain a trouble-free operating time far exceeding this.

The Ultimate Pursuit of Materials, Craftsmanship, and Quality

To ensure absolute reliability throughout the lifecycle of an MRI scanner, our high-voltage door handle capacitors undergo comprehensive reinforcement:

Aging-resistant ceramic dielectric: Utilizing highly stable ceramic materials with rigorously optimized proportions and doping, this material effectively suppresses dielectric aging and ion migration under high electric field strengths, ensuring highly stable capacitance over a decade.

Reinforced Electrodes and Connections: Advanced co-firing of metallized electrodes and ceramic dielectrics creates a strong chemical bond, resisting thermal fatigue and electrical stress. Multiple reinforcement processes are used on the screw terminals and internal electrodes to prevent loosening due to vibration.